Alt. Leather – Creating plastic free leather alternatives

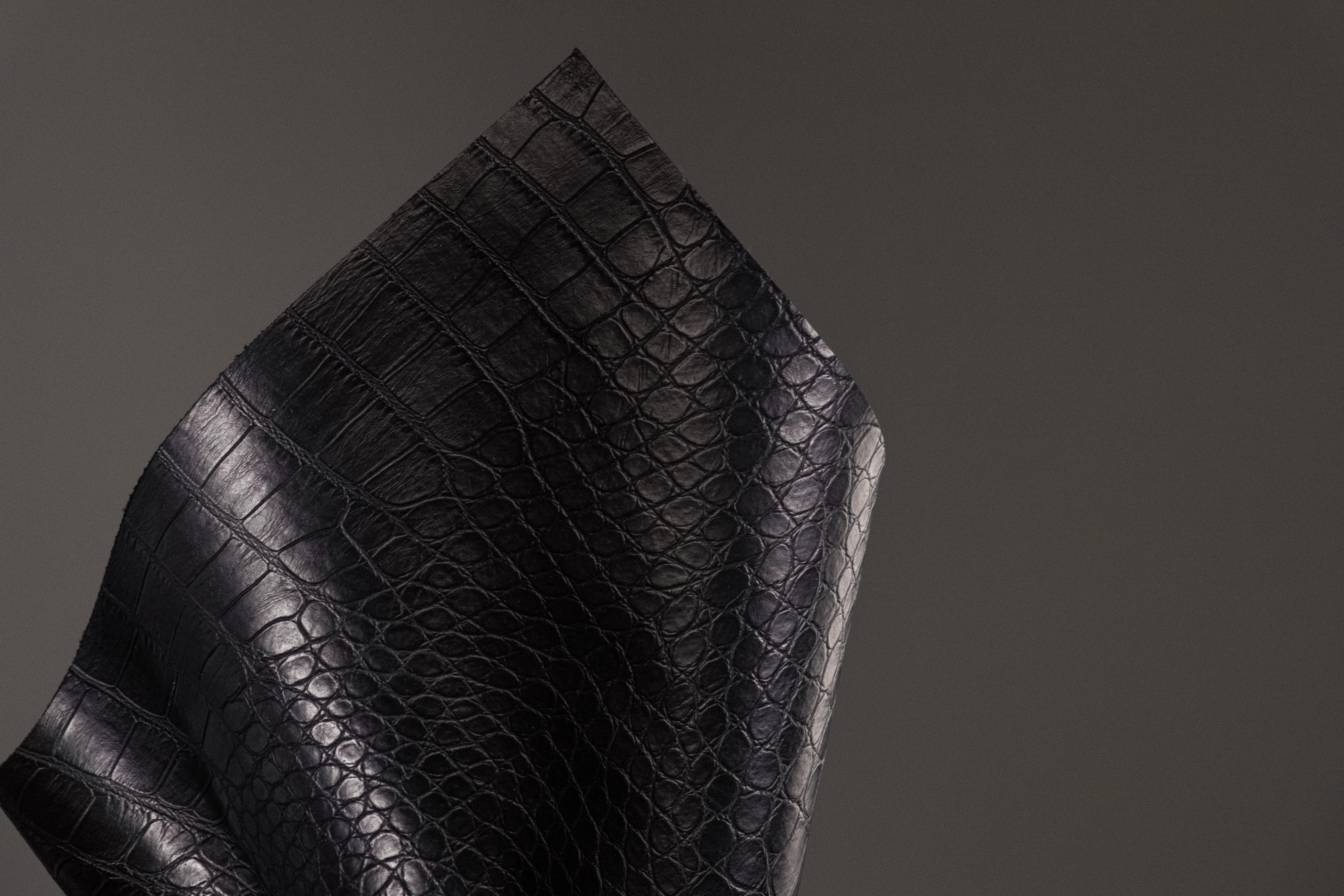

Melbourne based startup Alt. Leather is at the forefront of sustainable innovation with plastic free leather alternatives. They are developing a world leading sustainable leather alternative in terms of ingredient inputs, quality, ethical transparent supply chains and circularity. Alt. Leather’s proprietary leather alternative is made from agricultural waste and regeneratively grown plants, with no animal products or petroleum derived plastics. It is suitable for the fashion, furniture and automotive industries.

Founded by Tina Funder in 2023, Alt. Leather is redefining alternative leather options. Tina is an award winning creative director with 18 years of global advertising experience. Working with sustainable clients nurtured a passion for product development. Around 2019, she discovered cactus leather, a material made from the prickly pear cactus in Mexico, and was intrigued by its potential.

A natural entrepreneur and problem solver, prior to launching Alt. Leather, Tina had laid the groundwork with LOM Australia, a premium leather-alternative handbag label. Through 18 months of intensive research and design she discovered gaps in the market for fully plant-based, plastic-free materials that could meet the demands of today’s product designers. Many so-called 'sustainable' leathers still contained polyurethane as a binder, a form of plastic.

Determined to find a sustainable solution, Tina embarked on a global search for a 100% plastic-free leather alternative. With Australia’s rich agricultural landscape and access to world class scientific research institutes, Tina engaged a team of material scientists and biopolymer experts, and Alt. Leather began.

Innovative and sustainable materials

Alt. Leather's breakthrough lies in its development of a low impact, 100% plant-based leather alternative. The fashion and textiles industry generates 10% of worldwide carbon emissions with leather being one of the most destructive textiles on the planet.1

Recent Life Cycle Assessment results highlight the company's material is 68.5% less carbon intensive than traditional leather, including requiring half as much water cradle to grave. This innovation not only addresses environmental concerns but also offers a scalable solution for various industries.

Made from agricultural waste and free from plastics and other petrochemicals, Alt Leather applies principles of green chemistry to design ecologically compatible materials that can freely move through the biological cycle at the end of their life.

“Our material is completely petrochemical plastic free. We don't rely on fossil fuels to make our material. What means is that our material is will breakdown, whereas a plastic or synthetic leather won't. A six month test with the University of Newcastle has confirmed that our material is industrially compostable. Any remnants that still remain, if they return to the Earth, can be eaten by worms.” Tina Funder, Founder and CEO

Turning innovation into protectable IP

Alt. Leather's patentable technology combines natural fibres in a plant based resin matrix to mimic the 3D network structure of animal leathers in order to create durable and flexible leather alternatives. The team is pushing the boundaries of biomaterial innovation, at pace. Their ambition is to have a pilot plant operational in Melbourne by end of 2025 with scale up scheduled for 2027.

As Alt. Leather has evolved from a concept to a company with proprietary technology, the innovation has needed protection. FB Rice has been a critical partner on Alt. Leather’s IP journey, providing intellectual property advice and strategy from the early stages. Guidance has ensured that the unique plant-based leather formulation and production processes developed by Alt. Leather are safeguarded through patents and trademarks, strengthening the company’s competitive position globally.

A vision for the future

The team at Alt. Leather believe that the future of leather is plant-based, low impact, cruelty-free and petrochemical plastic free. By reducing reliance on animals for leather and closing the loop on agricultural waste streams, Alt Leather is not only beating plastic pollution but also setting a new standard for what is possible in material science and ecofriendly design. The rewards of fixing plastic pollution are profound: cleaner oceans and lands, healthier people and ecosystems, greater climate resilience, and stronger economies.